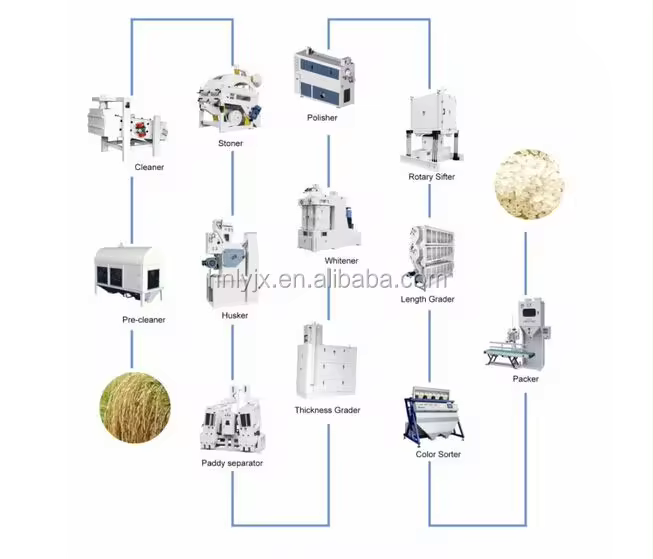

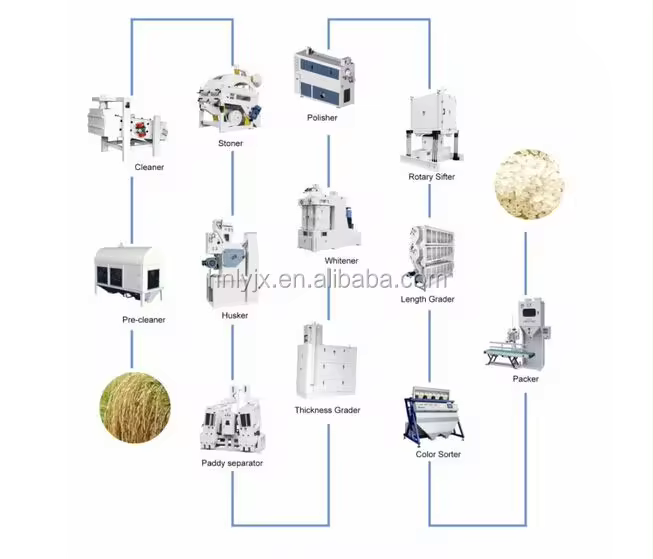

The modern rice milling process:

Modern rice milling processes consist of:

| Stage | Function |

| Pre-cleaning | removing all impurities and unfilled grains from the paddy |

| Husking | removing the husk from the paddy |

| Husk aspiration | separating the husk from the brown rice/unhusked paddy |

| Paddy separation | separating the unhusked paddy from the brown rice |

| De-stoning | separating small stones from the brown rice |

| Whitening | removing all or part of the branlayer and germ from the brown rice |

| Polishing | improving the appearance of milled rice by removing remaining ran particles and by polishing the exterior of the milled kernel |

| Sifting | separating small impurities or chips from the milled rice |

| Length grading | separating small and large brokens from the head rice |

| Blending | mix head rice with predetermined amount of brokens, as required by the customer |

| Weighing and bagging | preparing milled rice for transport to the customer |

| Model | MLGQ25-C | MLGQ36-C | MLGQ51-C |

| Capacity(t/h) | 3.5~5 | 5~7 | 7~10 |

| Grain content in hulls (grains in 100kg hulls) | ≤30 |

| Air volume(m3/h) | 4000 | 4800 | 5600 |

| Power(kW) | 7.5 | 7.5~11 | 11~15 |

| Exterior size (L×W×H,mm) | 880×1280 ×2002 | 1210×1400 ×2200 | 1344×1400 ×2200 |

the paddy husker in the rice mill line:

MLG Air Pressure Automatic Rubber Roller Rice Husking Machine uses novel fodder system, advanced timing belt and reliable shedding plate automatic trailing Rubber roller and gas-driven automatic elastic roller which make the rice roller techniques more high-efficiency and reliable. The yield per unit and technique witnesses obvious improvements.

Features

1.The paddy husker machine adopts a new vibratory feeding system, stepless adjustment could be done to the vibration frequency according to actual production. Feeding looks like waterfall, big and uniform, backed up shedding plate automatic tracking rubber roll devices to ensure feeding accuracy, making operation of rubber roll optimal, thereby having high shelling rate and big capacity.

2.The application of bearing house construction parallel moving as a whole ensures the force borne by rubber roll uniform, running stable, high husking yield, therefore avoiding differing in roll end diameters, increasing rubber roll useful life and economic efficiency.

3.High automation, easy operation and simple. Automatically unengaged without paddy, while if with paddy, rubber rolls engage automatically. Opening for feeding gate and pressure between the rubber rolls are automatically controlled by pneumatic components.

4.Driven by synchronous dentiform between rubber rolls and newly gear-box which is easy operation, firm and durable, there is no slip, no speed drop, therefore having high efficiency, low noise and reliable technologic effect.